The market is awash with fishing tackle. It’s available at various prices and made in factories around the globe. Cheap isn’t necessarily bad if you look after it, although it won’t stay the course like some of the big-name tackle items, but even these have to undergo maintenance and health checks to get the best from them…

There are two things that kill fishing gear – misuse and lack of maintenance. Quality tackle can handle the odd missed checkover, but cheap gear needs regular service stops otherwise corrosion soon sets in.

Modern tackle manufacturing processes ensure that even the most economical tackle looks professional. Finishes are excellent, rods have smooth, sometimes fancy whippings and high-build gloss coatings hold expensive-lookalike rod rings and fittings. Cheap reels have a metallic look but don’t be fooled because it could be an eye-catching coating over plastic.

The only real guide to quality is to buy reputable makes; buy the best you can afford and avoid the really cheap rods and reels which will eventually let you down.

Essential are quality rod rings that will not break if the rod is dropped. We are all clumsy and accidents happen. Rods get pulled over by the tide, blown over by wind or dropped on the garage floor and if a ring shatters it’s a disaster.

The solution is only buy rods that offer the best quality rings and fittings. Fortunately most of the major manufacturers use line guides from manufacturers such as Fuji and Seymo, whose rod rings can handle everyday knocks.

Look for the name of the manufacture stamped on the ring leg.

Rod and reel assembly

Nothing is simpler than assembling your beachcaster. Or is it?

Spigot joints are made so there is a gap between the two sections. This is because carbon wears with friction and if the edges of the joint butted up closely when the rod is new, resulting wear would produce a loose joint and the chance of the tip popping out mid cast.

Keeping the spigot clean of sand and grit will extend its life. When assembling, make sure that the spigot or joint is tight together. A major cause of rod breakages occurs when a joint is not pushed home firmly, casting then puts pressure on the blank wall causing it to fracture when the rod is flexed.

Make sure the sections fit together snugly and the rod rings are aligned, but avoid tapping the butt against the ground because this can cause the joint to jam.

It is important when separating joints not to grip the rod rings, this will cause them to twist and damage. Grip the blank close to the joint and twist and pull in a straight line.

Increasingly rods are supplied with a soft grip area close to either side of the joint, which makes joints easier to separate on a cold wet beach. If your rod joint is stuck get the help of another angler and gently twist and pull in a straight line, one holding each section.

Some modern beachcasters have an adjustable reel seat, which can be moved in any position on the butt. You can easily fit one to an existing rod but ensure it is the correct diameter. Mark its regular position on the butt with a wrap of PVC tape, which can also serve to add more grip to the seat if it is the incorrect diameter.

Some modern beachcasting rods now have an adjustable reel seat

Keep reel seats free of sand because the slot that guides the reel clamp can misalign on the cheap models causing it to jam, even override the thread, another reason to buy only the best.

With careful use modern carbon rods are virtually impossible to break, but there are rules that will keep your rod in one piece. These include never picking a rod up by the tip because pressure from a ring foot on the tip can cause a breakage.

Similarly never flex the rod tip with your hands or try to break out of a snag with the rod tip. You can break any rod by jerking the tip or placing too much pressure on it. The procedure for pulling for a break is to point the rod tip at the snag, wrap the line above the reel around the butt a couple of times and walk slowly backwards.

Rules for retrieving

The simplest way to retrieve is to place the rod butt between your legs when you retrieve to give you plenty of purchase.

If you fish with the reel low down then you can place the butt on your hip. Don’t crank the reel against a heavy weight or snag because the extra strain can damage the reel’s gear or pinion. Instead lift the rod dragging the weight in and then reel as you lower the rod. In extreme situations you can walk backwards and then reel as you walk forward. This is called pumping and is the way to beat large fish or lumps of weed.

Spigot joint

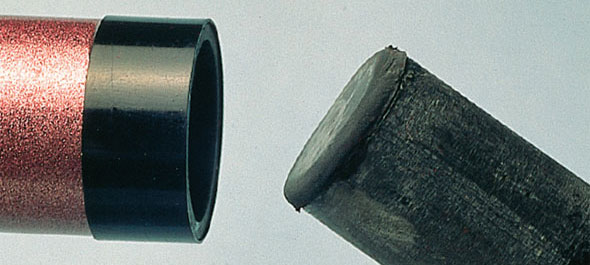

There are several different joints used by rod-makers. The spigot joint involves a short length of lower diameter carbon that slots in the top of the butt section to accommodate the tip section. This is called a male spigot and the tip (female) fits over it.

In most cases this level spigot joint is used to maintain the smooth taper of the rod, but it obviously adds weight to the finished rod and in many of the modern longer rods, which are increasingly popular, weight is saved by allowing the tapered lower section to push inside the female or next section up.

A spigot joint involves a short length of lower diameter carbon that slots in the top of the butt section

Double whipping

This involves a layer of whipping on the blank before the ring is added. This extends for the length of the ring. The ring feet are then whipped on top of this layer. A clue is the whipping between the ring’s legs.

Reel positions

The high reel position is suitable for the layback or pendulum cast while the low reel is often preferred for the offthe- ground, pendulum, backcast and overhead thump casting styles. In terms of casting distance the low reel is superior because the style is slower and more powerful with less skill required in terms of timing.

Single leg rigs

The tip sections of some rods use the lighter and more flexible single leg rod rings, which are used because they influence the tip’s action less than the standard, longer and wider three-legged rings. But they are more delicate and therefore easier to damage.

Reducer

A short length of carbon that slots in the rod butt with its correct name being an extension. It is for use with the low reel only and simply extends a low reel away from the angler’s body when reeling in.

General length is 12 inches to 18 inches, but most rods allow you to cut the reducer to the length you require.

Some rods have an extension that fits into the butt section when you want to reel in your line

Banded spigots

The edges of all joints on beachcasters have to be reinforced and, in most cases, this is done with a cotton whipping and high-build coating.

However, where weight is a concern to the rod builder a thin metal band is placed around the female end of the joint to stop is fracturing.

This spigot joint has a reinforced section for added strength

Beating corrosion

Main enemy is salt corrosion and even expensive tackle will corrode if the gear is left salty wet in a damp atmosphere.

Wash off rods and reels with warm soapy water after use and then dry. Rod bags can harbour salt and damp if they are not washed regularly. Reel bags coated in salt spray encourage corrosion.

Carbon expands when hot and this can cause rod joints to jam. A solution is to cool the male end of the joint down with a freezer block or even putting it under the freezer lid for a few minutes before attempting to pull apart.